Mastering Shaft Dynamics: Essential Insights for Precision Engineering and Maintenance

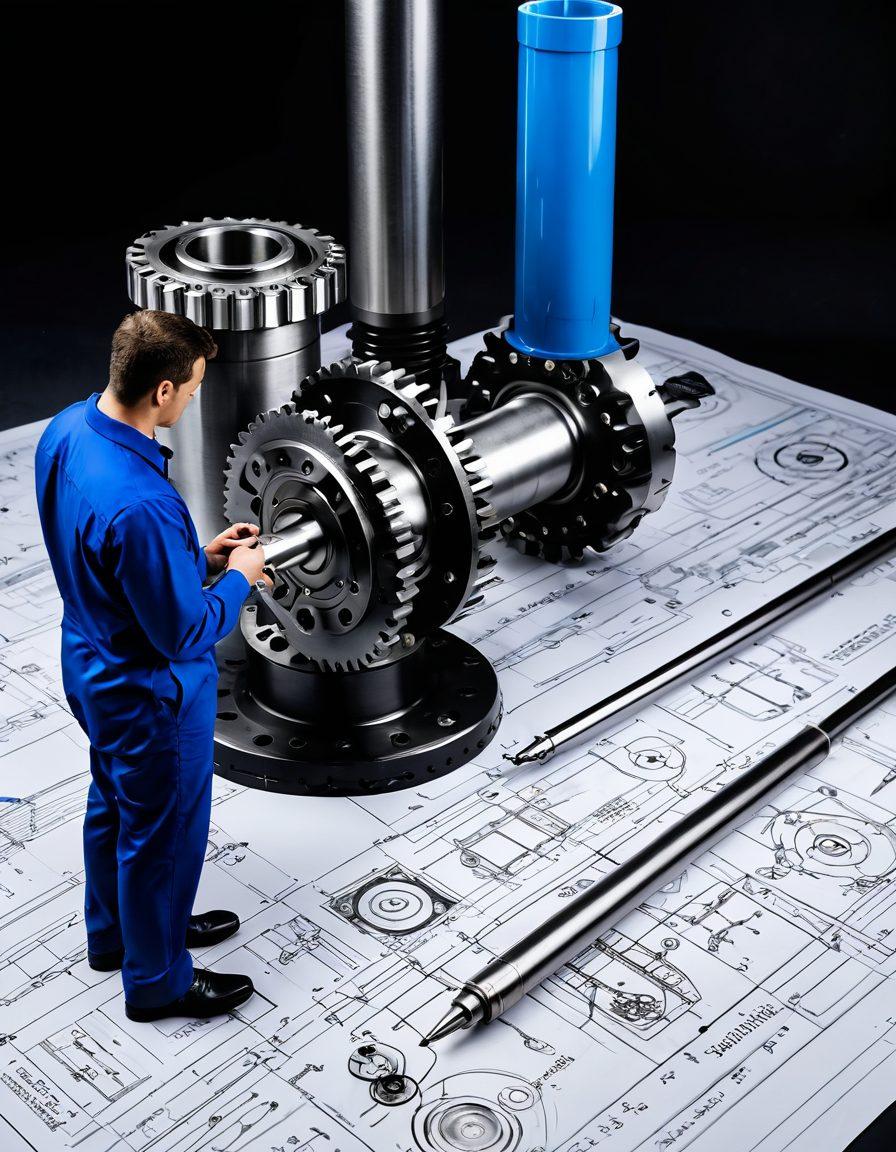

Imagine a world without rotating shafts. It's a vital component of mechanical systems, pivotal in industries ranging from automotive to aerospace. Yet, when it comes to discussing shafting, many can lose sight of its importance. Have you ever wondered what makes shaft dynamics so critical in precision engineering? Let’s delve into the fascinating realm of shaft components and explore the nuances of shaft designs and systems. Understanding these intricate parts will empower you to tackle industrial challenges with confidence.

At its core, a rotating shaft is designed to transmit torque and rotational energy, allowing for the smooth operation of various machinery. But the journey of a shaft from concept to implementation is not a straight line. From shaft manufacturing to shaft maintenance, each step requires careful attention to detail. It’s much like crafting a well-tuned musical instrument; one wrong note and the harmony of the entire system could falter. So, how do you ensure that your precision shafts continue to perform at their best?

Shaft analysis is a key player in ensuring the longevity and efficiency of your machine shafts. By implementing regular checks and balances, engineers can detect and rectify imbalances or misalignments that could otherwise lead to catastrophic failures. Have you ever experienced a breakdown because of poor shaft alignment? The consequences can be not only costly but also time-consuming. This is where efficient shaft engineering comes into play, transforming your maintenance routine into a proactive measure for avoiding mechanical mishaps.

Incorporating advanced techniques in precision engineering allows for optimizing shaft dynamics. By leveraging innovative shaft systems, engineers can design drive shafts that not only enhance performance but also reduce wear and tear. The integration of technology in shaft designs ensures that today’s industrial shaft solutions are not just adequate—they're exceptional. Are your shaft components designed to withstand the rigorous demands of modern machinery? The answer could redefine your operational capabilities.

However, even the best-engineered shafts can encounter issues if not appropriately maintained. It’s vital to cultivate a culture of shaft maintenance within your organization. Perhaps consider establishing a robust training program for your team that focuses on shaft analysis and mechanical design? Sharing insights through engineering blogs could also facilitate an exchange of solutions among peers in your industry. The truth is, our understanding of shaft dynamics doesn't just benefit individual companies, it enhances entire sectors. So, where do you begin your journey to mastering the secrets of rotating shafts? Let's foster curiosity and innovation, leading the way towards precision engineering excellence.

Essential Techniques in Shaft Dynamics: Ensuring Excellence in Maintenance and Performance

Shaft dynamics may sound like a niche topic confined to the world of mechanical engineering, but it touches on the very heartbeat of industrial machines. Picture a rotating shaft, the unsung hero of countless mechanical systems, tirelessly working to transmit torque and facilitate motion. From the automotive industry to manufacturing plants, precision shafts play an instrumental role. But what happens when shaft dynamics are neglected? Let's unravel the essential techniques in shaft dynamics and how they ensure excellence in maintenance and performance.

When we think of rotating shafts, what often comes to mind is their impressive capacity to transfer power from one part of a machine to another. However, grasping the intricate dynamics and maintenance of these shaft systems is essential for any engineer or technician. Imagine a scenario where a poorly aligned shaft leads to vibration and premature wear, disrupting operations and increasing costs. Have you ever wondered how a slight misalignment could spiral into crippling machinery failures? By employing proper shaft components and understanding shaft designs, we set the foundation for effective shaft maintenance and optimal performance.

One of the cornerstones of shaft engineering is shaft alignment. Just like a finely tuned engine, your shaft systems need to be precisely aligned to function correctly. Misalignment can lead to unnecessary friction, heating, and ultimately, early failure of your machine shafts. When was the last time you evaluated the alignment of your drive shafts? Regular shaft analysis and maintenance checks can save your organization a significant amount of time and money. Ensuring that our shafts are aligned not only enhances longevity but also maximizes the efficiency of torque transmission throughout the system. It's about striking a balance between durability and functionality.

Shaft dynamics doesn't merely revolve around alignment; it encompasses an understanding of the thermal and vibrational behaviors present in various shaft designs. How can one ensure that the engineering solutions employed cater effectively to the challenges at hand? Incorporating a systematic approach to shaft manufacturing, focusing on material selection and structural integrity, can immensely affect performance outcomes. Imagine relying on precision shafts that can withstand the test of time, offering reliability and consistency across industries. This approach demands that we meld engineering principles with thorough testing and analysis to create unparalleled industrial shaft solutions.

In conclusion, embracing the essentials of shaft dynamics is pivotal in maintaining the smooth operation of mechanical systems. As engineers, we must commit to continuous learning through engineering blogs and professional development, ensuring that we recognize the importance of shaft maintenance in our projects. What strategies can you implement today to enhance the reliability of your shaft systems? By adopting dynamic maintenance practices, integrating cutting-edge techniques, and fostering a culture of excellence, we can transform our approach to shaft engineering. Thus, ensuring that our rotating shafts not only perform but excel.

From Design to Maintenance: Mastering the Art of Shaft Engineering for Industrial Success

In the world of mechanical engineering, few components are as critical yet often overlooked as the rotating shaft. It may seem like a simple piece of cylindrical metal, but its role in the functionality of machinery is nothing short of vital. Every time a vehicle accelerates or a conveyor belt moves, it's the precision of the shaft systems making it happen. This blog is dedicated to exploring the journey of shaft engineering, from design to maintenance, helping you unlock industrial success through effective shaft dynamics management.

Have you ever wondered why some machines last for decades while others seem to break down at the slightest provocation? The secret often lies in the mastery of shaft engineering. The design of precision shafts requires a deep understanding of mechanical systems and the dynamics involved. Good shaft designs accommodate factors like torque transmission and load distribution, underscoring the importance of a well-thought-out approach right from the manufacturing stage. Imagine being able to create a shaft that not only performs optimally but also extends the lifespan of your machinery – wouldn’t that be a game changer in your industry?

One of the core principles of effective shaft engineering is proper shaft alignment. Misalignment can lead to vibrations, increased wear and tear, and ultimately, costly downtimes. A well-aligned drive shaft ensures that energy is transmitted efficiently, reducing the risk of failure. Just think of it this way: when all parts work in harmony, the entire mechanical system operates smoothly. So, how can you ensure your shaft systems are aligned correctly? Regular shaft analysis and maintenance are crucial, along with incorporating modern engineering solutions that mitigate potential issues before they arise.

Now, let’s delve into shaft maintenance. It’s not just about fixing issues when they occur; proactive maintenance is the heartbeat of efficient shaft systems. Regular inspections and the use of advanced monitoring technologies can detect irregularities in shaft components early on. This not only saves you time and money but also allows for the continuous operation of your industrial applications. Picture a plant manager dedicated to preventive measures, keeping downtime around zero – that’s a leader in shaft engineering!

Ultimately, mastering the art of shaft engineering means marrying tradition with innovation. The future of industrial shaft solutions lies in understanding and integrating new manufacturing techniques and materials. Whether you’re involved in designing new machine shafts or maintaining existing systems, embracing a mindset focused on continuous learning and adaptation is key. So, what’s your next step in enhancing your shaft dynamics knowledge? Dive into engineering blogs, connect with experts in shaft maintenance, and push the boundaries of your mechanical design to achieve unparalleled operational success!